|  |

JHY Services & Support

FAQs & Tips

Six Enemies of Frying Oil:

Air:Air bubbles that are pumped into oil during filtering causes oxidation and impacts fried food flavor.

Heat:If the fryer's temperature is too high, the oil oxidation will happen rapidly.

Soap:Grease cleaning can produce an alkaline flavor and causes oil to darken.

Carbon:Bread Crumbs and small pieces of food will carbonize and cause chemical reactions, resulting in oil breakdown.

Water:Water from food, steam, and residual water after cleaning will cause hydrolysis, which will cause oil to darken and smoke.

Salt:Salt exists in marinades and breading breaks will cause solubilization, Which triggers a chemical reaction that begins the breakdown and reduces the service life of the oil.

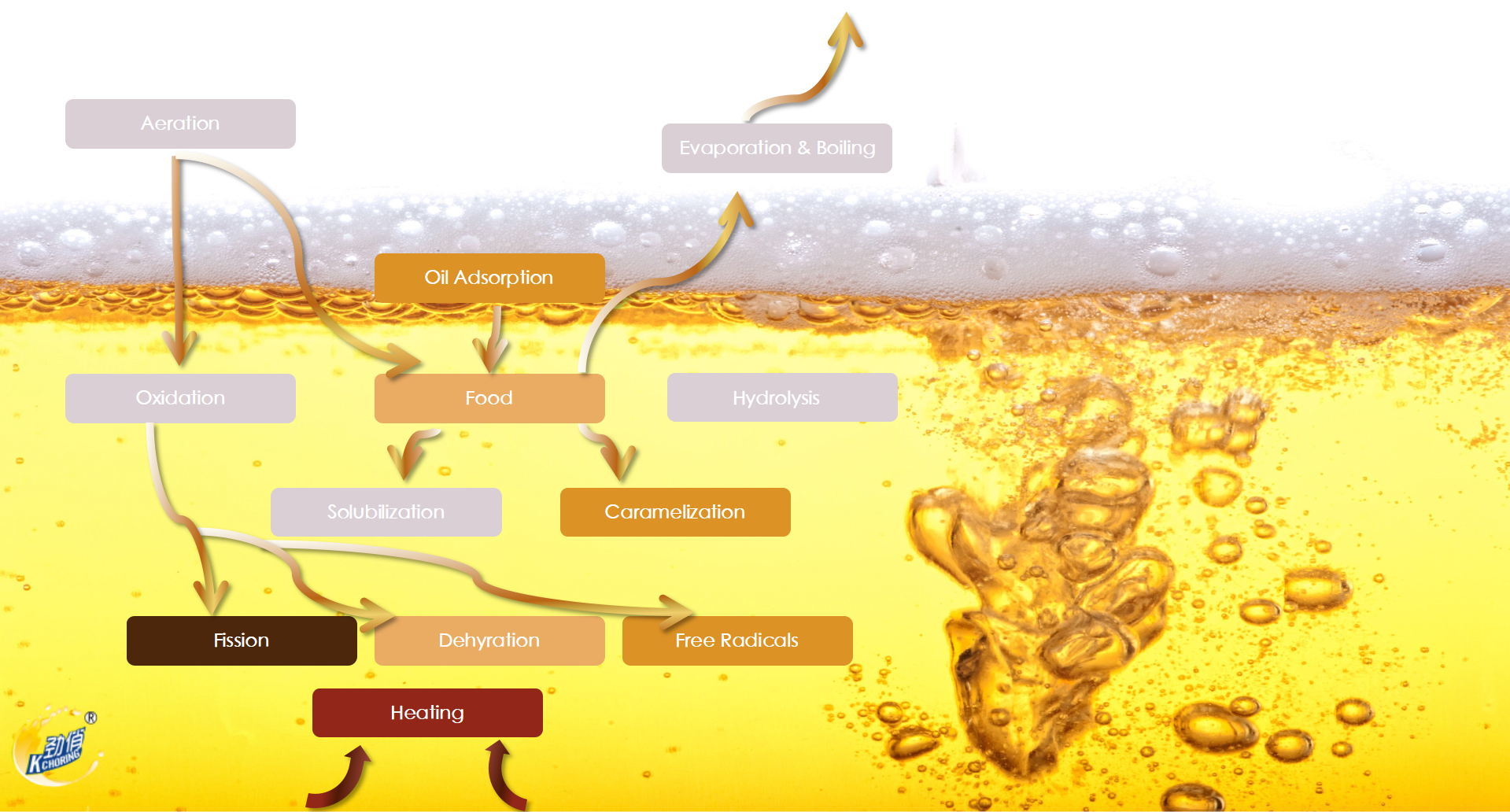

The main reactions during the use of frying oil include starch gelatinization, Maillard reaction, protein denaturation, caramelization reaction, etc. Unsaturated fatty acids are oxidized to peroxides and hydroperoxides, which continue to decompose into fatty acids, aldehydes, ketones, and other small molecules, and are finally oxidized to acids. As a result, the oil deteriorates, increasing the acid value, peroxide value, and viscosity of the frying oil, darkening the color of the oil, increasing the trans fatty acids, aggravating the foam of the oil, and affecting the smell and taste.

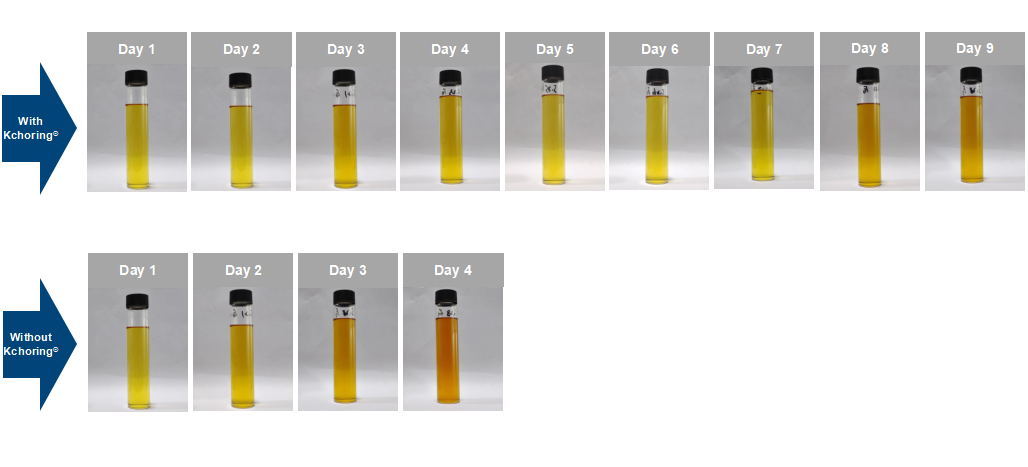

The service life of frying oil depends on the sales volume, product mix, and fry station management practices. The oil could be dark, smoking, foaming, or has a bad smell after 3 days without Kchoring®. Therefore, it is time to change the oil.

To those who use the Kchoring® filter daily, the oil’s service life could be extended by at least 30 - 50%, and the cost saving by up to 50%. The decision to change oil depends on finished food quality standards and sensory evaluation of Color, flavor, taste, appearance texture, etc. Join us now, and enjoy an annual bonus with Kchoring®.

If the oil is not changed in time, it will cause excessive benzopyrene, excessive acid value, excessive aflatoxin, and extremely high peroxide values. During frying, the oil will surround and penetrate the food and become part of the food. As the frying oil breaks down, dissolved impurities will penetrate the food, affecting its taste, texture, and appearance.

Using Kchoring® every day can safely remove dissolved impurities in the oil and extend the oil’s service life. Only the fresh, clean frying oil can provide customers with consistently safe, delicious, crispy, and golden fried foods. If daily filtration is not carried out, the service life of the frying oil will be reduced. To reduce the cost of frying oil, maintain the quality and taste of food, and satisfy customers - use Kchoring® every day.

Free fatty acids (FFA) or “Acid value” is an important parameter used in evaluating the quality of oil. FFA are molecules that lower the surface tension of oils, allowing batter and breading to soak up more oil. TPM refers to the extent of oxidative thermal degradation of frying oil and is one of the objective criteria for assessing the deterioration of cooking oil, which affects the taste and temptation of fried foods.

We are the first drafting unit of the national standard for Food-grade Magnesium Silicate, which is the main ingredient of oil filter powder. Kchoring® can effectively eliminate FFAs, TPMs, colors, off-flavors, and odors, which greatly slow down the formation of these molecules, allowing the oil to last longer and making fried foods taste more crisp.

Yes. Oil degradation is pretty common with all edible frying oils, but rest assured that we not only have extensive experience in edible oil purification but also provide a one-on-one customized solution. Kchoring® is effective on all types of oil, including the new zero trans-fat oils.