Kchoring® Oil Filter Powder for Industrial Frying

Product Series: Food Grade Products

- Product at a Glance

-

Description

Kchoring® Oil Filter Powder for Industrial Frying, a non-toxic, odorless white powder, is considered a new-tech and eco-friendly product, which is an amorphous porous adsorbent that absorbs and prevents the formation of harmful components such as TPMs, FFAs, Trans Fats, aflatoxin, benzo(a)pyrene (PAHs) and other impurities, ensuring frying oil stays fresh, and fried food tastes fantastic.

Technical Information

Product Properties Standard Specifications Appearance white powder SiO2(lgnited basis),% ≥67.0 MgO(lgnited basis),% ≥15.0 Loss on Drying(105℃,2h),% ≤20 Loss on lgnition(On dry basis),% ≤15 Soluble Salts,% ≤3.0 Free Alkali(Determination of NaOH),% ≤1.0 Fluoride(mg/kg) ≤10.0 Pb,mg/kg ≤5.0 Packing and Storage

- -The packaging bag is made of outer coated paper with an inner plastic lining, with a net weight of 20kg per bag. Bulk transportation arrangements will be according to specific requirements. This product should be stored in a cool, dry, and clean area, focusing on moisture prevention. After opening the bag, any unused product should be sealed.

- -We are the first drafting unit for the national food safety standard GB 1886.62-2015 for food-grade magnesium silicate.

Oil Management of Kchoring® Oil Filter Powder for Industrial Frying

1. Check if the adsorption mixing tank, oil filtering device, and other equipment are functional, and ensure there are no leaks in the connected pipelines and valves.

2. Pump the oil to be treated into the adsorption mixing tank and maintain the oil temperature within the range of 80°C to 140°C.

3. Depending on the acid value of the oil to be treated (if the acid value is higher than 5, it is recommended to dispose of the oil as waste), add oil filter powder to the mixing tank at a rate of 1 to 10% of the oil's weight. Start stirring for 30 minutes to allow the oil filter powder to contact the oil and adsorb harmful substances fully.

4. Turn on the circulation filtration pump of the oil filtering device and let the oil circulate in the filtration loop for approximately 15 minutes until the oil becomes clear and free of impurities. Begin collecting the qualified oil.

5. When the pressure in the oil filtering device reaches the set upper limit, stop the circulation filtration pump. Use a pressure difference or compressed air inside the oil filtering device to empty the residual oil in the device and its connected pipelines back into the adsorption mixing tank.

6. Open the oil filtering device and clean the filter bags (or filter paper) and filter cake. Thoroughly wash the oil filtering device and, if necessary, use compressed air to dry it. Replace with clean filter bags (or filter paper) for the next use.Download Product Brochure

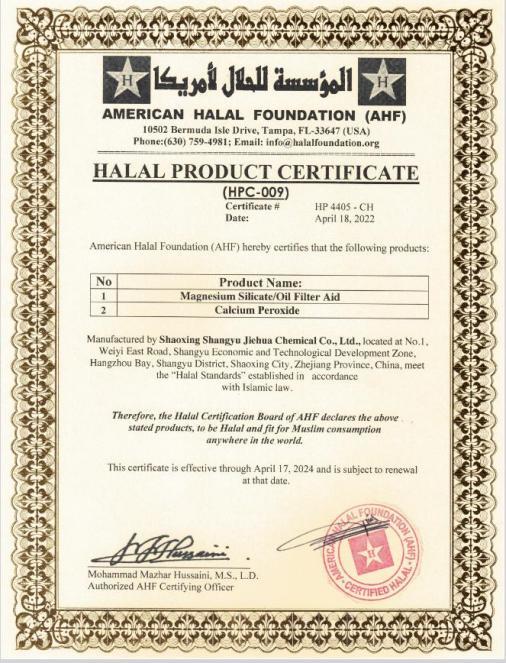

Recognitions

Key words: potassium hydrogen peroxymonosulfate compound salt, sodium percarbonate, sodium perborate, calcium peroxide, magnesium peroxide, solid hydrogen peroxide, magnesium silicate, magnesium aluminum silicate, composite powder, oil filter powder, anthraquinone regeneration catalyst

Previous Page

Next Page

Contact JHY

Real progress starts with listening. We welcome your inquiry or feedback and want to offer you the best possible service.

For any inquiries regarding JHY's specific business divisions, R&D and business collaborations, media and communications, purchasing, career opportunities, etc.

Please provide detail information in all the appropriate fields to help us expedite our response to you. The fields marked with * are mandatory so that we can process your request. We will treat your data confidentially.