Gel Breakers in Shale Oil Drilling

JHY,Stimulating Shale Gas Development

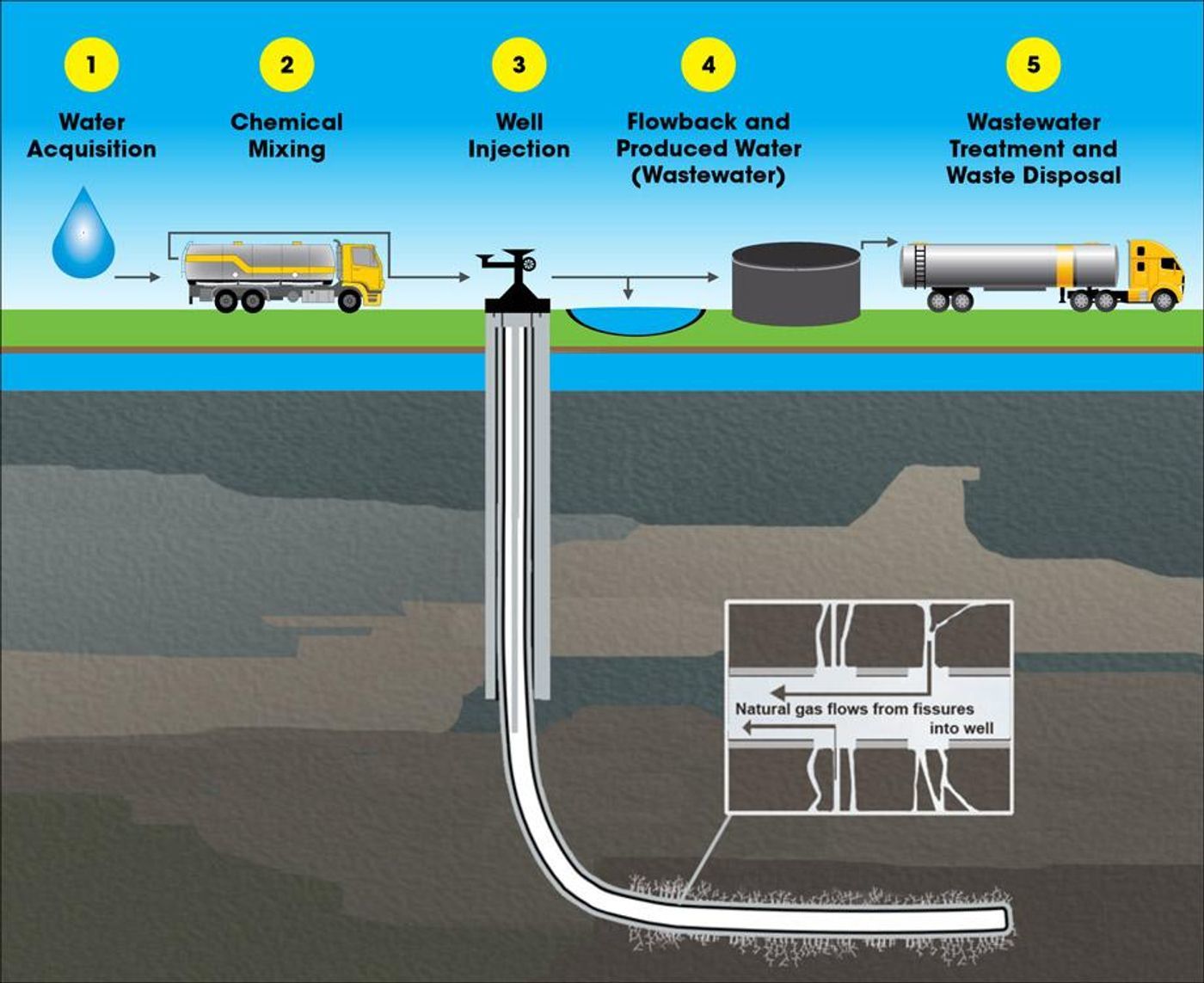

As production from conventional oil and gas fields continues to mature and the shift to nonconventional resources increases, the importance of hydraulic fracturing will escalate as oil and gas supplies are developed from these precious resources.

|  |

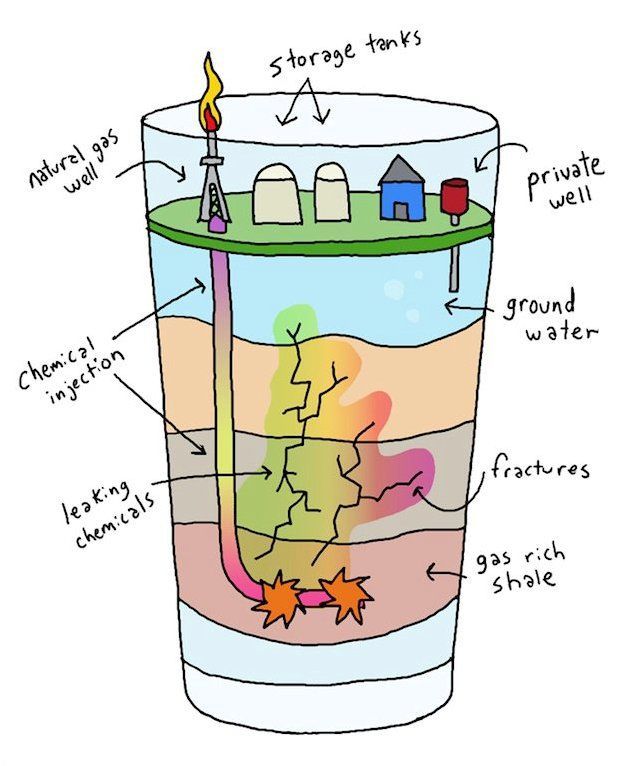

What’s Hydraulic Fracturing and How it Works?

|  |

Chemicals Used in Hydraulic Fracturing

Chemicals serve many functions in hydraulic fracturing. The chemical additives may consist of acids,surfactants,biocides,bactericides,pH stabilizers,gel breakers,etc. |

- Friction Reducer:The addition of friction reducers allows fracturing fluids and sand, or other solid materials called proppants, to be pumped to the target zone at a higher rate and reduced pressure than if water alone were used.

- Biocides:Biocides to prevent microorganism growth and reduce biofouling of the fractures.

- Corrosion Inhibitors:Oxygen scavengers and other stabilizers to prevent corrosion of metal pipes.

- Scale Inhibitor:Scale inhibitor prevents iron and scale accumulation in the formation and wellbore. It enhances permeability by eliminating scale in the formation and casing.

- Acids:Gas shales may contain various naturally occurring trace metals and compounds leached from rocks by acidic water. Numerous compounds have been formed naturally in the shale, which require various chemicals to counteract any negative effects these compounds may have in the well or the reservoir. Acids that are used to remove drilling mud damage within the near-wellbore area.

- Gel Breakers:Breakers are usually mixed with the fracturing fluid during pumping. The breakers include magnesium peroxide, calcium peroxide, sodium perborate, persulfate salts, copper compounds, and glycol. The gel is needed to create the fracture and carry the proppants, it also has to degrade and be produced back to leave a clean and high-conductivity propped fracture behind.

Hydraulic Fracturing Solution with JHY

| Sodium Perborate is an important chemical for hydraulic fracturing for shale gas drilling which can maintain fluid viscosity as temperature increases and delayed breaker.

Magnesium Peroxide is also used as a polymer breaker in the field of oil/gas drill fluid Industry, when breaking the viscosity created by polymer like xanthan gum etc, this kind of new type of polymer breaker should be considered, and it has a significant effect on viscosity with a short time for de-polymerization. Magnesium peroxide is introduced for chemicals used in hydraulic fracturing as a breaker and will not taint the groundwater. |

* We have multiple products including sodium perborate, magnesium peroxide, calcium peroxide to meet the varying performance and price requirements of different users. For commodity of those products, please find JHY domain experts for more details.

JHY,Your Trusted Partner

We not only have standardized products but also provide a one-on-one customized solution. No matter what challenges we meet, we solve them together. Should you have any questions or needs related to Gel Breakers in Shale Oil Drilling, please do not hesitate to contact our service consultant.

|  |

Key words: potassium hydrogen peroxymonosulfate compound salt, sodium percarbonate, sodium perborate, calcium peroxide, magnesium peroxide, solid hydrogen peroxide, magnesium silicate, magnesium aluminum silicate, composite powder, oil filter powder, anthraquinone regeneration catalyst

Related Products