The Positive Electrode Additive in Lead-Acid Battery

Small size, Big power-Long-Lasting Energy Booster

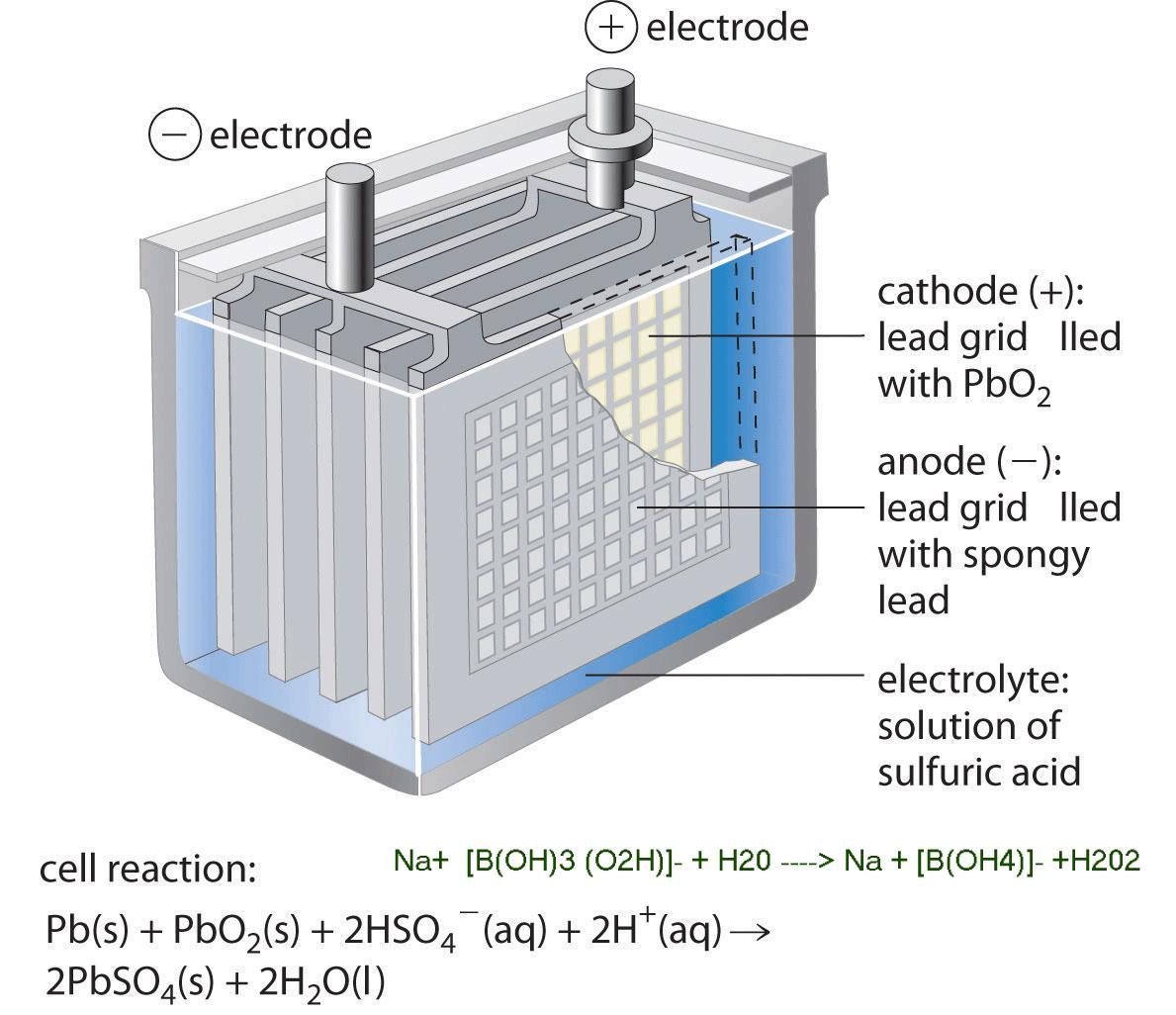

- Conventional lead-acid batteries contain a positive electrode (PbO2 plate) and a negative electrode (Pb plate) immersed in a sulfuric acid electrolyte and have a separator interposed between them. A variety of additives have been proposed as a means of improving the manufacture of batteries. If an oxidizing solution can be applied to the positive plate, the result of a paste containing lead oxide(s) and lead sulfate(s) on the surface of a battery plate and electrochemically forming the paste into an active material, which is called a lead oxide paste composition.

- The input energy can be reduced during the forming process. When lead-acid batteries are improperly charged or discharged, useful power delivered to loads diminishes. One cause for this is a phenomenon generally referred to as sulfation. One possible method is to recharge the lead-acid battery using a pulse charger, with the constant current-constant voltage (CC-CV) that can reduce the charging time and extend the lead-acid battery life.

| Sodium Perborate is used as a positive electrode additive to enhance the bonding ability between the separator and the lead paste. Adding sodium perborate (NaBO3 ) can help improve the performance and life of lead-acid batteries, thereby softening the active material of the plate and generating lead sulfate, increasing the capacity of the battery, especially in low temperatures.

The Pros of Sodium Perborate:

|

JHY,Your Trusted Partner

We not only have standardized products but also provide a one-on-one customized solution. No matter what challenges we meet, we solve them together.

|  |

Key words: potassium hydrogen peroxymonosulfate compound salt, sodium percarbonate, sodium perborate, calcium peroxide, magnesium peroxide, solid hydrogen peroxide, magnesium silicate, magnesium aluminum silicate, composite powder, oil filter powder, anthraquinone regeneration catalyst

Related Products