Purification&Decolorization in Oil Refining Processes

JHY, Leading in Porous Adsorbents

- Synthetic porous adsorbent refers to synthetic, amorphous magnesium silicate, magnesium aluminum silicate, aluminum silicate, etc. It is a safe, pure fine white compound with a porous internal structure and enormous activated surface, products are ideal for use as adsorbents, anti-static flow agents, anti-caking agents, catalyst supports, carriers, and reinforcing fillers. It can get rid of chemicals with polarity as you want.

- We are a leading company in the porous adsorption material industry, with many patents and certificates. We are the first drafting unit of the national standard for food-grade magnesium silicate. Our first production line of Synthesis Magnesium Silicate Adsorbent was put into use in 1994, and the second production line was successfully launched in 2003. Our porous adsorption materials are not only used for purification essential oil but are also suitable for the production of green and clean energy.

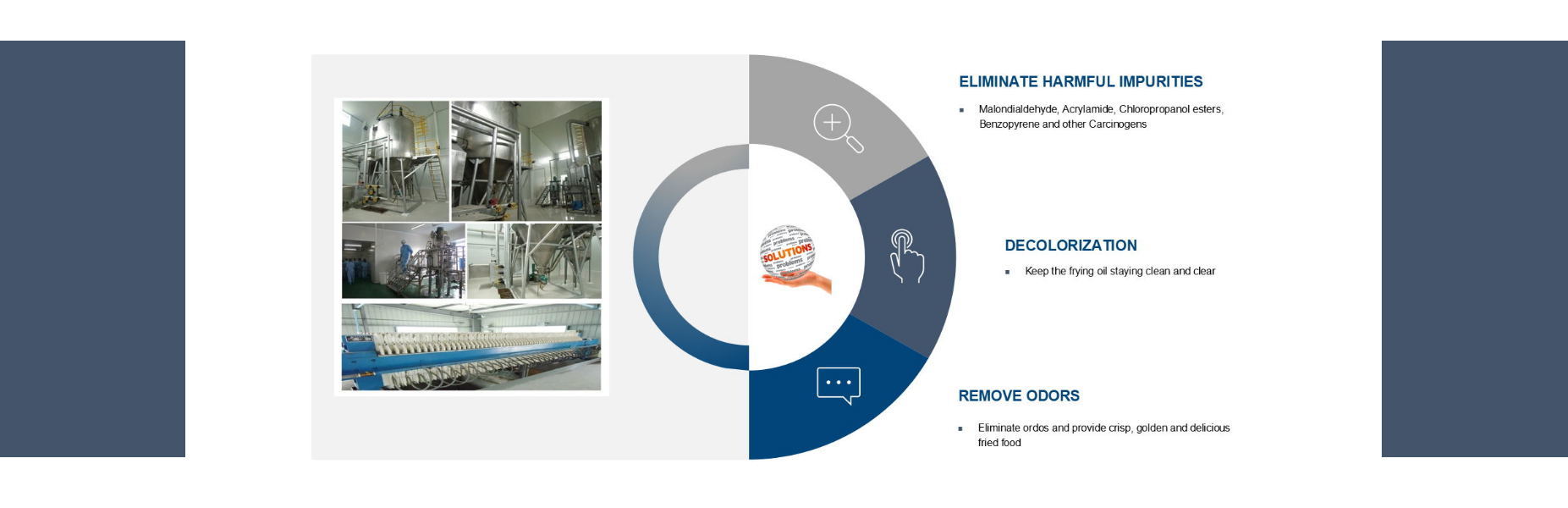

- The principle of purification treatment by JHY is deep filtration. It uses the nanoscale pores with extremely large specific surface areas distributed on the surface of the powder to easily absorb harmful substances in the oil, such as alkali metals, phosphates, glycerides, soaps, chlorophyll, residual free fatty acids, methanol, water, etc., like a magnet, and decolorizes the oil and removes odors.

JHY, Enhances in Purification Oil

*Please find JHY domain experts for more details.

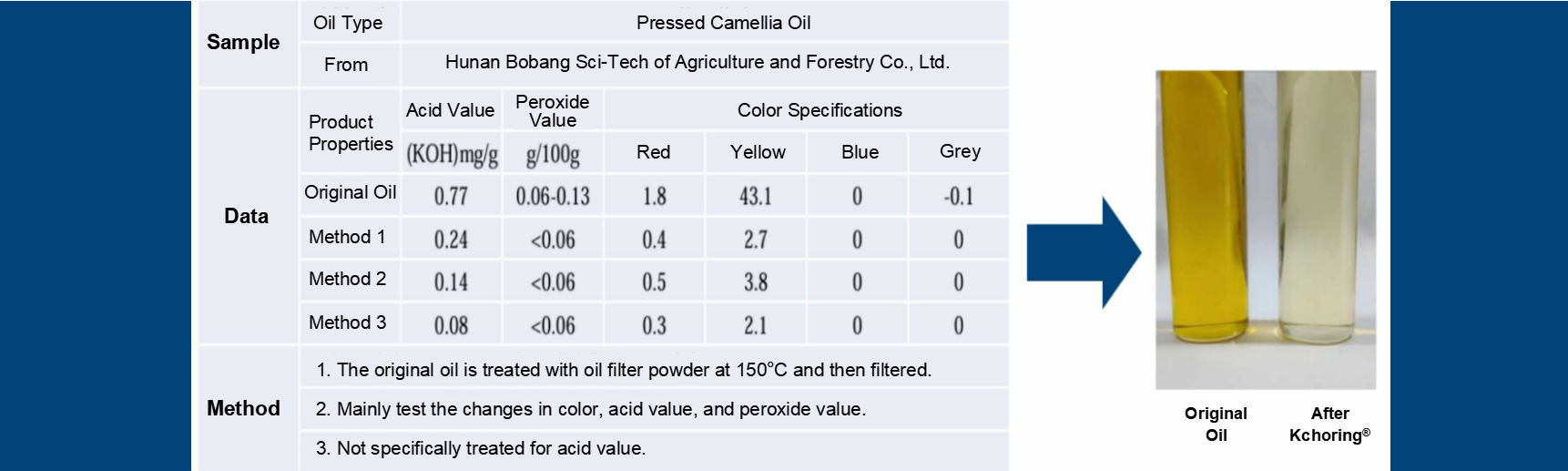

The Magic in Purification Camellia Oil

*The decolorization and impurity removal effects of camellia oil are extremely significant, which is crucial to improving the quality of oil refining.

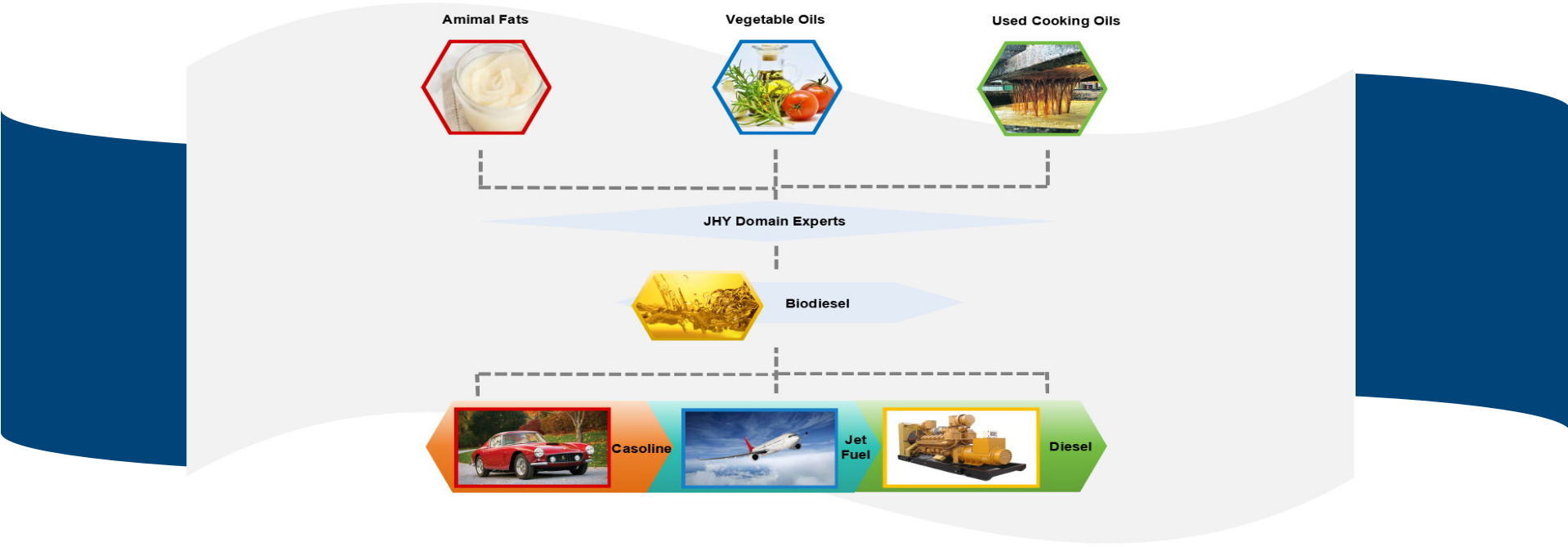

JHY Empowers Nature’s Green Energy: Biofuels

Biodiesel has attracted attention worldwide as an eco-friendly alternative to fossil fuels for being renewable, non-toxic, biodegradable, and carbon-neutral. Impure fuel may cause engine oil to deteriorate, water and catalysts may corrode fuel injectors, soaps, and glycerides may clog fuel injectors, and methanol may cause seal failure. EN ISO 12937 specifies a maximum of 500 ppm (parts per million) of water in biodiesel. As FAME is hygroscopic it can pick up water in storage and because of this, there can be problems meeting the specification. At around 1500 ppm, the solubility limit is reached and the water becomes visible. Producers still using traditional "wet wash" systems may find this aspect of the EN Specification rather troublesome to achieve. Free water promotes biological growth and adverse reaction to transesterification which undoes biodiesel back into free fatty acids, which is disastrous in a fuel delivery system.

|

JHY, Your Simply Best Choice for Drying & Polishing of Biodiesel

|

*Drying & polishing system of biodiesel, our magnesium silicate could be a easy and good choice, usage is less than 10-15ka per 1000liter of biodiesel. Please find JHY domain experts for more details.

JHY Customized Biofuel Technical Services

*Please find JHY domain experts for more details.

JHY,Your Trusted Partner

We not only have standardized products but also provide a one-on-one customized solution. No matter what challenges we meet, we solve them together. Should you have any questions or needs related to Impurity removal, Decolorization, Agricultural residues removal in Oil Refining Processes and Biofuel Innovation, please do not hesitate to contact our service consultant.

|  |

Key words: potassium hydrogen peroxymonosulfate compound salt, sodium percarbonate, sodium perborate, calcium peroxide, magnesium peroxide, solid hydrogen peroxide, magnesium silicate, magnesium aluminum silicate, composite powder, oil filter powder, anthraquinone regeneration catalyst

Related Products